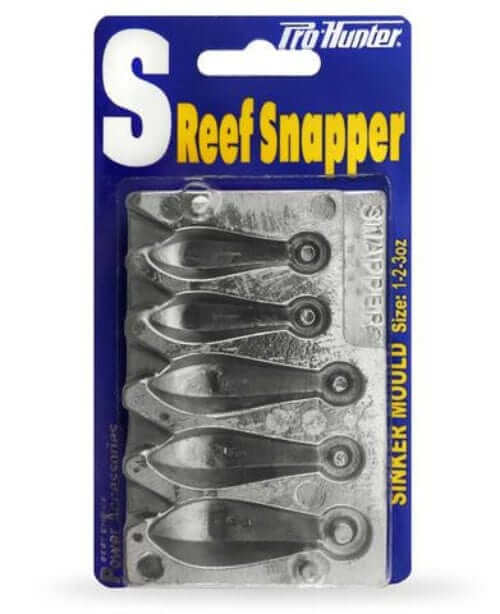

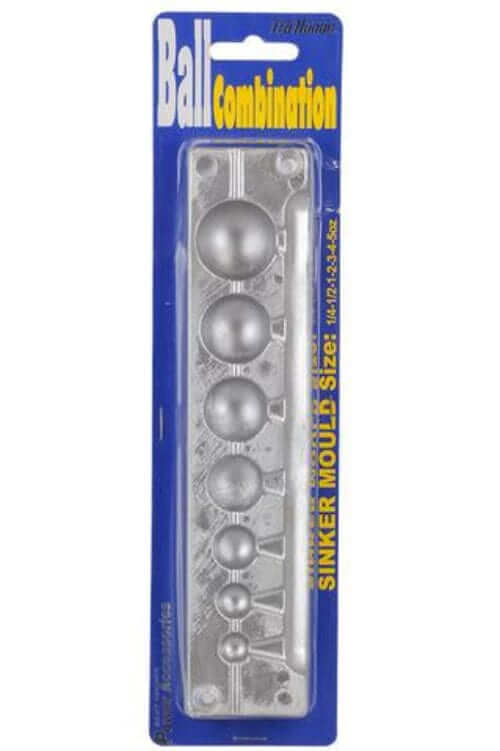

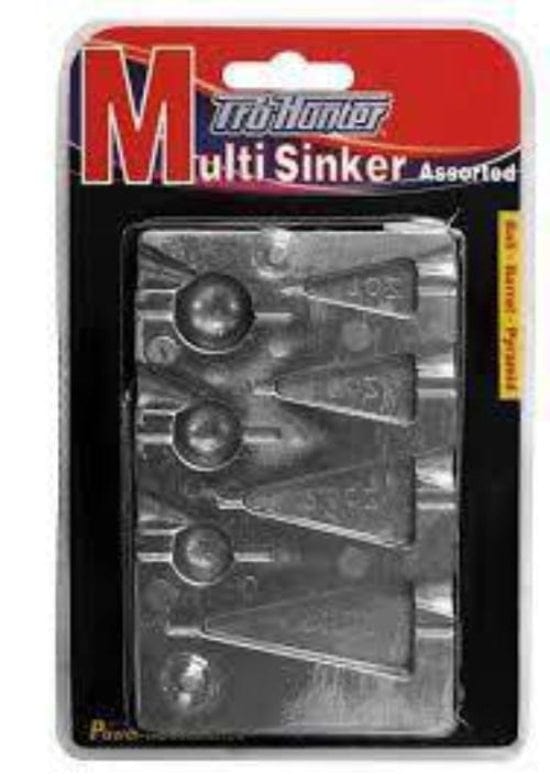

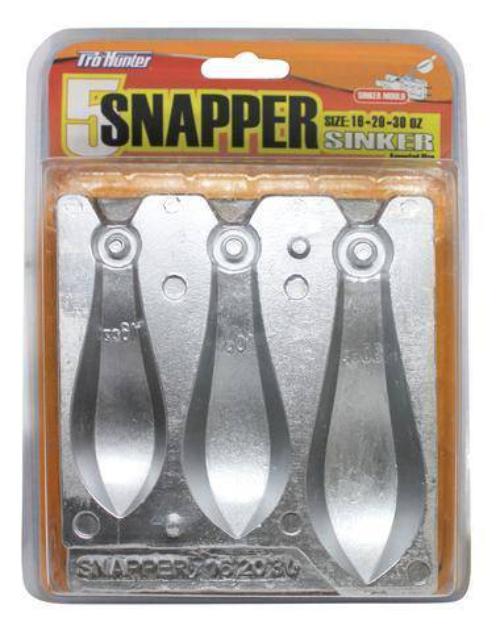

Fishing Sinker Moulds in Various Shapes & Sizes

7 products

Showing 1 - 7 of 7 products

Fishing Sinker Moulds in Various Shapes & Sizes

ONE HOLE BOAT WIDE

This sinker is extremely easy to make. Using a greased nail the lead is poured in, once the lead has cooled in a few seconds the nail is pulled out with pliers & the mould is turned upside down. Presto! Sinkers as fast as you can pour them.

TOMBSTONE

Tombstone or Graveyard sinker. Simply clamp the two halves together & pour the lead to the size you would like. Half full is 40 oz.

HAPUKA BOMB

This sinker is designed to aerodynamically descend to the bottom in the shape to avoid snagging. Flat sides prevent the sinker rolling on the bottom of the boat.

Things to know about before using your sinker moulds

- Warning! Put safety first!

- Always use protective gloves & eyewear when using this product.

- Molten lead can cause severe burns.

- To avoid lead poisoning, only use in well-ventilated areas.

- Do not allow any water to get into the molten lead as it will cause drops of molten lead to explode.

Follow these procedures when making sinkers

- Preheat the moulds

- Tightly clamp the 2 halves

- Carefully pour molten lead into the clamped mould

- Unclamp when cool &remove your perfectly formed sinkers

Instructions for Mansfield Do-It-Yourself Sinkers

Sourcing Lead

Most of you will have some scrap lead lying around. Try visiting your local roofer/plumber or scrap dealer. Lead is worth around a $1 or $2 per kilo. Another excellent source is to use discarded wheel weights from your local tyre shop. These weights have a hardener added to them & work superbly as sinker and jig material. Although less durable for jigs, pure lead does work very well for us, so don't be put off using it!

Melting Your Lead

The secret to making sinkers & jigs in volume is to have a large amount of lead in a molten state. To achieve this use a Mansfield Melting Pot which is curved inside to allow a ladle to scoop lead easily. Although not as effective, a cast iron pot will do at a pinch. Use a gas ring or BBQ to melt the lead. Ensure that you use adequate ventilation when melting lead as the fumes are toxic. A common mistake is not to melt your lead to a "bronze" colour which is substantially hotter than a liquid state. DO NOT under any circumstances allow moisture or water to get in contact with molten lead; it splatters dangerously!

Pouring the Lead into your Mould

Scrape off any impurities from your lead by simply scooping off the top layer of "rubbish" that forms once your lead has melted. Heat up your mould before pouring the molten lead into the mould. You may be using a hinged mould which can be clamped together using a D clamp. Use a ladle to pour the molten lead into your mould. Open mould once the lead has cooled sufficiently (this only takes a few seconds). Once the sinkers are completely cool, then remove them from the moulds.

Recently viewed

Blog posts

View all

Fishing Net Long Guide: Expert Tips & Uses for 2026

How to Choose the Perfect 4 34 Inch Unslung Mono Flounder Mesh for Seamless Fishing